You may hear “Infrared Thermography Inspection” and think, Oh, that’s just an add-on service that I don’t need to worry about. According to a study conducted in 2019 by the U.S. Department of Energy, over 2/3 of electrical failures can be identified and corrected before they occur with an annual infrared inspection.

With businesses relying more and more on electrical systems to power their facilities, the importance of regular maintenance and inspections cannot be overstated. Since its creation, Infrared Thermography has revolutionized preventive maintenance for electrical systems. This technology has rapidly gained traction due to its ability to detect issues before they escalate, ensuring zero business interruption and seamless operations. Henderson Services, Kentucky's leading electrical services provider, is at the forefront of utilizing infrared thermography inspections to elevate electrical system reliability and efficiency.

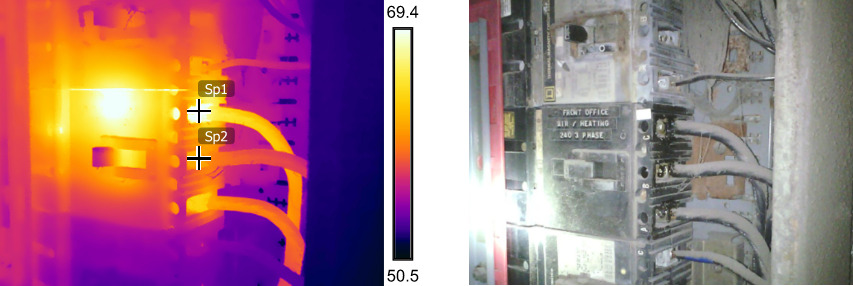

Infrared Thermography is a cutting-edge technology that utilizes thermal imaging cameras to capture the infrared radiation emitted by objects. At Henderson, our Level II trained Infrared Thermographers utilize visual inspections, ultrasonic survey detection, and infrared scanning technology to detect the impending failure of your critical electrical distribution components. Every object with a temperature above absolute zero (-273.15°C or -459.67°F) emits heat in the form of infrared radiation. By detecting and visualizing these temperature inconsistencies, Infrared Thermography allows professionals to identify anomalies in electrical systems, mechanical components, and even building structures.

One of the most significant advantages of infrared thermography inspections is their non-intrusive nature. Traditional methods of inspecting electrical systems often involve shutting down equipment and interrupting business operations. This downtime not only disrupts productivity but also incurs additional costs. In contrast, Infrared Thermography inspections can be carried out without interrupting the ongoing operations, making it a preferred choice for businesses that cannot afford any downtime.

In your business, every minute counts. The ability to maintain and assess electrical systems without causing any interruption can be a game-changer. This makes infrared thermography a valuable tool for companies striving to achieve operational excellence and minimize disruptions.

Imagine being able to identify potential issues in your electrical systems while they are still operational. Infrared Thermography turns this dream into a reality. Skilled technicians equipped with thermal cameras can conduct inspections while machines and equipment are running at full, energized capacity. These inspections can give a glimpse into what it’s like having Superman’s X-ray vision, a powerful ability to discover issues without the need for invasive maneuvers. This real-time monitoring capability allows for the early detection of overheating components, loose connections, and other anomalies that might lead to catastrophic failures if left unaddressed.

The ability to perform inspections while machines are operational is a huge advantage, as it enables businesses to solve problems proactively, preventing unexpected breakdowns and costly repairs. Additionally, this approach enhances safety by reducing the need for manual intervention during inspection periods.

As providers and passionate advocates for preventive maintenance in any business, we recognize the power infrared thermography has in transforming the mindset facility managers have when thinking about protecting their businesses. By implementing regular infrared thermography inspections, businesses can:

Detecting issues early helps prevent potential breakdowns, ensuring uninterrupted operations and customer satisfaction. In addition, knowing the inspection has been done offers you peace of mind that your machinery is functioning properly throughout the day.

Non-intrusive inspections mean less downtime, translating to higher productivity and reduced operational costs.

Identifying and resolving problems before they escalate can extend the lifespan of electrical equipment and systems.

By identifying safety hazards and addressing them promptly, the risk of accidents is significantly reduced.

Proactive maintenance reduces the need for emergency repairs, saving on repair and replacement costs. Your typical Infrared scan of an entire electrical system is usually a fraction of the cost of a replacement should a part fail.

Infrared thermography has transformed the landscape of preventive maintenance, allowing businesses to predict and prevent issues before they disrupt operations. Henderson Services is dedicated to helping Kentucky businesses utilize the power of this technology to achieve unparalleled reliability and efficiency in their electrical systems.

This advanced technique provides invaluable insights into the health of electrical systems. With the ability to perform inspections without causing any interruptions, and even while machines are running, this technology has become an indispensable tool for businesses striving for excellence in preventive maintenance. By utilizing these services, Henderson Services is saving businesses millions of dollars in potential damage repairs every single day. We are committed to leading the charge in utilizing infrared thermography inspections to ensure the reliability and longevity of electrical systems, ultimately contributing to seamless operations and reduced operational costs your business will face.

Contact us today to learn more about how your business can begin implementing preventive maintenance as part of your regular business operations!