Electrical maintenance is an essential responsibility that facility managers, safety managers, and business owners must prioritize. Ensuring that your electrical systems are well-maintained not only keeps your operations running smoothly but also guarantees the safety of your employees and compliance with regulatory standards.

In this comprehensive guide, we delve into the critical aspects of electrical maintenance, underscoring why it’s a necessity rather than a mere suggestion. Here are ten crucial points you need to know about electrical maintenance.

Adhering to NFPA 70B is non-negotiable. Often referred to as the "maintenance bible," NFPA 70B outlines all necessary maintenance tasks and intervals for electrical equipment. Compliance with these guidelines is essential for meeting OSHA requirements and ensuring the safety of your facility.

Regular, proactive electrical maintenance helps uncover potential issues before they escalate into catastrophic problems. By catching minor faults early, you can address them swiftly and prevent costly downtime or hazardous situations.

Many insurance providers recognize the value of diligent electrical maintenance and offer discounts to companies that comply with NFPA 70B's required maintenance tasks. This practice not only reduces your insurance premiums but also aligns your operations with best safety practices.

Key electrical equipment often has extended lead times for replacement. Regular maintenance prevents sudden failures, allowing you to plan and source replacements without the stress of unexpected downtime. Being proactive ensures your operations are never caught off guard.

By keeping your electrical equipment "exercised" and in optimal working order, regular maintenance significantly enhances employee safety. Well-maintained systems reduce the risk of accidents and create a safer work environment for everyone.

Through consistent maintenance, you can identify recurring issues and failing parts within your system. This knowledge allows you to keep critical spare parts on hand, minimizing disruptions caused by waiting for long-lead-time items.

Regular maintenance provides insight into the lifespan of your equipment. Knowing when machinery is nearing the end of its usable life allows you to budget for replacements well in advance, transforming potential emergency expenses into planned investments.

Collaborating with a reliable contractor like Henderson Services offers the advantage of experienced electricians who become familiar with your facility. This familiarity minimizes downtime if issues arise and ensures that your maintenance program is carried out effectively and efficiently.

Quick and easy access to your chosen Electrical Services contractor is a must! Henderson Services operates two offices in Kentucky, serving the entire state. Our widespread presence ensures that no matter where your facility is located, expert electrical maintenance services are within reach.

Navigating electrical maintenance can be daunting. It is imperative that you enlist a trusted expert to help guide you through your regular electrical maintenance needs. Henderson Services performs electrical maintenance for some of the most renowned brands in Kentucky daily. Our expertise and experience position us as a trusted partner in maintaining the integrity and safety of your electrical systems.

Understanding the importance of electrical maintenance and implementing a comprehensive maintenance program is critical for any business. At Henderson Services, we are committed to providing top-tier electrical maintenance services that ensure compliance, safety, and operational efficiency. Don’t leave your facility’s electrical health to chance—reach out to us today to discuss how we can help you establish a robust electrical maintenance program.

When managing your facility, ensuring operational efficiency while maintaining cost-effectiveness is paramount. One significant stride towards achieving this balance is the transition from traditional fluorescent lighting to LED technology. This switch not only shows your commitment to sustainability but also marks a crucial step in boosting your facility's operational excellence. For Facility Managers and Safety Managers navigating the complexities of electrical maintenance, understanding the tangible benefits of this transition can be a game changer.

LED lighting stands at the forefront of efficiency, offering a number of benefits over its fluorescent counterparts. Primarily, LEDs consume significantly less power, which translates into lower energy bills—a critical factor in any facility's operational budget. This reduction in energy consumption does not compromise on brightness or quality, as LEDs are designed to provide a superior and more consistent light output.

Furthermore, LEDs have a longer lifespan, often outlasting fluorescent bulbs by thousands of hours. This longevity reduces the frequency of replacements, minimizing both the environmental impact and the maintenance workload for facility teams. This ultimately allows for the reallocation of resources to other critical areas of maintenance and improvement.

The initial transition from fluorescent to LED lighting is an investment. However, the return on investment (ROI) is both swift and substantial. The immediate reduction in energy consumption leads to noticeable savings in utility costs. When coupled with the decreased need for frequent replacements and maintenance, the cost benefits of LEDs become clear.

Beyond direct financial savings, LEDs offer indirect cost benefits related to safety and productivity. Improved lighting quality can enhance worker safety, reducing the risk of accidents and associated liabilities. Furthermore, better lighting has been linked to increased worker productivity, as it creates a more comfortable and visually efficient environment.

Transitioning from fluorescent to LED lighting involves several key steps, each critical to ensuring the success and efficiency of the move:

The shift from fluorescent to LED lighting is not merely a trend but a strategic move towards operational efficiency, cost reduction, and environmental responsibility. For facilities looking to optimize their performance and safety while achieving significant cost savings, this transition is an investment that promises a considerable return. The process, while requiring upfront planning and investment, paves the way for a brighter, more efficient, and sustainable future.

Facility Managers and Safety Managers spearheading this change can do so with the confidence that they are making a decision that aligns with the highest standards of integrity, safety, and quality. You also don't have to make these decisions alone. Henderson Services is here to advise and help implement these changes to save your business from unnecessary costs and roadblocks to efficiency.

Step into the world of Henderson Electrical Services, where tradition meets expertise! For over a century, we've been at the forefront of Kentucky's electrical industry, earning a reputation for reliability and innovation. Our core services span three key areas: Electrical Services, boasting advanced technology infrastructure and precise electrical construction work; EV charging station installation, driving us towards tomorrow; and comprehensive Preventive Maintenance, encompassing both energized and de-energized upkeep alongside Arc Flash Hazard Analysis. But we're not just about service – safety and education are paramount. From NFPA-70 certification to other essential training, we're dedicated to empowering our community. Let’s take a deeper dive into what Henderson is really all about and take a look at 10 things you may not have known about us!

Henderson's spirit is founded on the core values of Integrity, Attitude, and Service. This means that every interaction is guided by honesty, a positive approach, and a strong desire to serve our customers the best way we can.

For Henderson, establishing enduring relationships with all our customers has been a passion that we cultivate every day. Our focus has always been to go beyond a mere transactional relationship, forging bonds that last a lifetime.

A proud icon in the industry, Henderson has been in continuous operation since 1919. This year, we are celebrating our 105th birthday, marking over a century of premium service.

Our commitment to safety and quality is validated by our national industry leading EMR rating of .62. This distinction is a testament to our tireless pursuit for excellence and adherence to best practices in the field. The industry average rating is 1.0.

We take pride in our in-house training and education department. This unique division fuels the conversation and knowledge of our electricians and customers on electrical safety, CPR, First Aid, and injury prevention, ensuring everyone's safety.

Our dedicated 24/7 service and preventive maintenance teams in both Louisville and Lexington ensure that we are always available for our customers in the greater Jefferson County area and all of Central Kentucky.

Henderson Services is a leading EV charger installer for commercial, institutional, civil, and industrial customers in Kentucky. We continually strive for innovative solutions and sustainable options.

Our commitment to our customers is exemplified by our enduring partnerships. We've been with Churchill Downs since the 1940's and have proudly been at Toyota Motor Manufacturing in Georgetown since its inception.

We've had the honor to host generations of families as employees. Grandfathers, fathers, sons, siblings, and even married couples have chosen to make Henderson their work home, adding to our rich legacy and familial culture.

Being a corporate citizen is a responsibility that Henderson takes very seriously. We make annual donations to several local charities in both Lexington and Louisville, believing that a successful business gives back to its community.

Join us in our journey as we continue to power industries, homes, and lives with the same dedication and passion that we have had since 1919.

Anyone you ask about financial advice will probably have one common suggestion: make sure you have an emergency fund. This isn’t because they think you’re irresponsible or that you can’t plan ahead. It’s because they’ve experienced the feeling of being surprised by an unplanned expense. When you have money set aside for emergencies, it can be a relief to know that things will be okay, but when you don’t, panic can begin to set in quickly.

This can be similar for businesses that don’t set aside funds for facility maintenance. You may feel fine when things are going smoothly, and everything is functioning correctly, but when that unexpected repair needs to happen, it can be challenging to find the money to cover the cost.

Whether it's routine upkeep or emergency repairs, having a comprehensive maintenance plan in place ensures uninterrupted operations and peace of mind. Here are a few things that you get when you properly budget for facility maintenance:

When it comes to facility maintenance, safety should always be the top priority. At Henderson Electrical Services, our team consists of highly trained electricians who prioritize safety above all else. With years of experience and expertise under their belts, they adhere to the highest safety standards, ensuring that your facility remains hazard-free and compliant with regulations.

From inspecting electrical systems to identifying potential risks, our electricians are thorough in their approach, leaving no stone unturned when it comes to keeping your facility safe and operational. By investing in our services, you can rest assured that your employees, customers, and assets are protected from electrical hazards.

In our line of work, time is always of the essence. That's why our team prides itself on having responsive project managers who are dedicated to meeting your needs promptly and efficiently. Whether you require scheduled maintenance or urgent repairs, our team is just a phone call away, ready to spring into action whenever you need us.

Our project managers work closely with you to understand your facility's unique requirements and tailor our services accordingly. From developing preventive maintenance schedules to coordinating service visits, they ensure that everything runs smoothly, allowing you to focus on your core business activities without worrying about electrical issues.

Transparency is key when it comes to facility maintenance, which is why we provide detailed reporting for every job we undertake. From the initial inspection to the final repairs, you'll receive comprehensive reports outlining our findings, recommendations, and actions taken. This not only keeps you informed every step of the way but also allows you to track the performance of your electrical systems over time.

Our detailed reports enable you to make informed decisions about budgeting and prioritizing maintenance tasks, helping you optimize your facility's efficiency and longevity. Whether it's identifying potential areas of concern or documenting compliance with regulatory standards, our reporting system is designed to provide you with the information you need to keep your facility running smoothly.

Even with the most meticulous maintenance plan in place, emergencies can still occur. That's why at Henderson Electrical Services, we offer 24/7 emergency service to address unforeseen issues and minimize downtime. Whether it's a power outage, equipment failure, or any other electrical emergency, you can count on us to respond quickly and effectively, day or night.

Our team of skilled electricians are equipped with the tools and expertise needed to handle any emergency situation, restoring power and functionality to your facility as soon as possible. With our rapid response times and efficient solutions, you can mitigate the impact of emergencies and keep your business running smoothly, no matter what challenges arise.

By partnering with Henderson Electrical Services, you gain access to safety-focused electricians, responsive project managers, detailed reporting, and 24/7 emergency service, ensuring that your electrical systems remain in optimal condition at all times. Don't wait until problems arise; contact us today to develop a preventive maintenance plan for your facility and experience the peace of mind that comes with knowing your electrical systems are in capable hands.

In the realm of facility management and safety, ensuring the continuous operation of electrical distribution components is not just a matter of efficiency but of utmost safety and financial foresight. Infrared Thermography (IR), a sophisticated yet underutilized service, stands out as an indispensable tool in the predictive maintenance toolbox. This post explores the invaluable benefits of incorporating infrared scanning into your business’s maintenance strategy, underscoring how it embodies the principles of integrity, safety, and operational excellence.

Infrared Thermography offers a significant advantage by enabling visual and contactless inspection of electrical systems. This method allows for detailed analyses without the need for physical contact with the components being inspected. For facility and safety managers, this means being able to conduct thorough inspections without interrupting the workflow or exposing personnel to potential hazards. The ability to evaluate the condition of equipment safely while it remains operational is crucial for maintaining uninterrupted services and ensuring the safety of all those involved.

One of the most compelling advantages of infrared scanning is its capacity to be performed while systems are energized and in operation. This aspect of IR technology is especially critical for businesses where downtime equates to significant financial losses. Unlike traditional inspection methods that may require shutting off power and halting production, infrared thermography ensures that your operations can continue without interruption. This seamless integration into regular maintenance routines positions infrared scanning as an essential component of a proactive maintenance strategy.

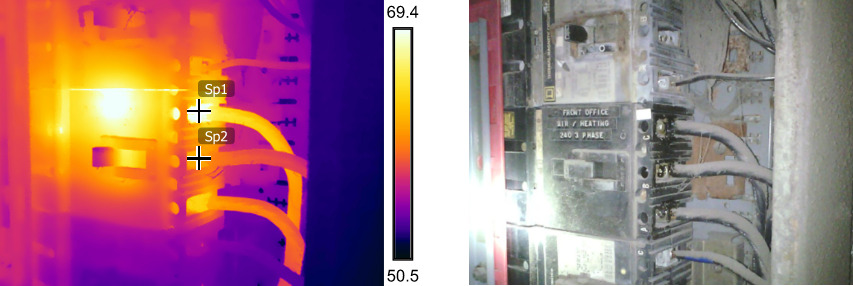

The heart of Infrared Thermography's value lies in its ability to preemptively identify issues before they escalate into failures. Henderson Services utilizes this technology to its fullest potential, bringing high-level expertise directly to the forefront of your maintenance efforts. Our Level II trained Infrared Thermographers are equipped with the necessary training and tools to detect even the most subtle anomalies in your electrical distribution systems that could indicate potential failure. Through a combination of visual inspections, ultrasonic survey detection, and infrared scanning technology, we can pinpoint areas of concern long before they manifest as downtime-inducing problems.

In essence, infrared thermography acts as an early warning system. By identifying hot spots, loose connections, overloaded circuits, and other issues invisible to the naked eye, we provide businesses with the opportunity to address these problems proactively. Such an approach not only averts costly repairs and replacements but also significantly reduces the risk of fire and other safety hazards, reinforcing our commitment to prioritizing your safety and operational integrity.

At Henderson Services, Infrared Thermography is more than just a service—it is a commitment to excellence and safety. Our approach to IR scanning is thorough and comprehensive, ensuring that no detail is overlooked. The meticulousness of our process is matched only by our dedication to providing actionable insights that make a tangible difference in your operational efficiency and safety protocols.

Infrared Thermography, with its blend of safety, efficiency, and predictive capability, is an investment in the future of your business. By choosing Henderson Services as your partner in preventive maintenance, you are not only securing the reliability of your electrical systems but are also entrusting your operations to a team that values integrity, professionalism, and unmatched expertise.

In today’s fast-paced and demanding business environment, staying ahead of potential failures is not just a strategy—it's a necessity. Infrared thermography is a testament to how innovative technologies, when deployed with expert insight, can transform maintenance practices. It encapsulates our commitment to offering services that are not just about prevention but are fundamentally about enhancing the safety, quality, and sustainability of your operations.

We invite facility managers, safety managers, and industry professionals to explore how infrared scanning can be integrated into your maintenance routines. With Henderson Services, rest assured that your critical systems are under the vigilant eye of industry-leading experts, where safety and efficiency are paramount. Allow us to demonstrate the difference that true professional integrity and quality-focused practices can make in your facilities. Together, we can ensure that your operations remain uninterrupted, safe, and at the forefront of efficiency.

For more information on how our Infrared Thermography services can benefit your business, contact Henderson Services today. Your proactive approach to maintenance begins here.

At Henderson Services, we believe that running a successful business requires careful planning and resource management. Preventive Maintenance is the number one area where many businesses fall short. Neglecting regular care of your facility can lead to costly consequences down the road. With over 100 years of experience in the industry, our advice is worth following, and we have seen how saying yes to preventive maintenance can save your business from financial disasters.

To patch or to repair. Do you save money by simply putting a “band-aid” on the problem, or do you spend the resources to truly repair the issue? While in the moment, it may feel good to spend little to no money on a potential issue, but the reality is that you’re simply delaying the inevitable. If something is broken, and you don’t complete an exhaustive repair, it will likely break again. And chances are, it’ll be in worse condition than it was originally.

Preventive maintenance is like insurance for your business operations. By proactively addressing issues before they escalate into major problems, you can save a significant amount of money in the long run. Waiting until equipment breaks down or a facility emergency occurs is a surefire way to experience repair costs, downtime, and even potential safety hazards.

At Henderson Services, we offer comprehensive preventive maintenance programs tailored to your specific needs. Our expert technicians can identify and address minor issues before they become major headaches. Taking a proactive approach not only extends the lifespan of your equipment but also reduces the risk of unexpected breakdowns that can disrupt smooth business operations.

When it comes to preventive maintenance, experience matters. Henderson Services has been serving businesses in Kentucky for over a century, and during that time, we've worked to build a reputation for excellence in discovering costly issues before they arise. Our team of certified professionals has seen it all, from routine maintenance tasks to complex projects like arc flash analysis and NFPA 70E compliance.

Our deep knowledge of industry best practices and evolving safety regulations allows us to provide invaluable guidance to our clients. When we recommend preventive maintenance measures, it's based on a century's worth of experience and a commitment to helping your business thrive.

Let's take a look at a real-life example from our region to emphasize the importance of our services. Due to financial circumstances, a business in Central Kentucky chose to ignore our preventive maintenance offerings. The proposed maintenance would have cost $36,000. Shortly after, disaster struck.

A major accident occurred, and instead of paying the original $36,000 that we proposed, which would have prevented this devastating accident, the resulting loss exceeded $22 million.

This unfortunate incident serves as a stark reminder of the risks associated with neglecting maintenance responsibilities. It's not just about saving money; it's about protecting your employees, customers, and the reputation of your business.

In any modern business, electrical safety is paramount. Ignoring standards like NFPA 70E (National Fire Protection Association) can have devastating consequences, including injuries, fatalities, and costly legal ramifications.

Henderson Services specializes in arc flash analysis and NFPA 70E compliance, ensuring that your electrical systems are safe and up to code standards. By saying yes to our preventive maintenance services in this critical area, you can protect your business from potential disasters and liabilities.

Utilizing Henderson Services’ preventive maintenance is an investment in the longevity and success of your business and the lives of your employees. It not only saves you money by preventing costly future repairs but also protects your business from accidents and compliance issues. With over a century of experience and a commitment to safety, we are your reliable partner for all of your facility maintenance needs.

Don't wait until disaster strikes— contact us today to take proactive steps to safeguard your business today!

Businesses across the world rely heavily on electrical systems to keep their operations running smoothly. Whether it's a manufacturing facility, office building, or data center, electrical systems are the lifeblood of any modern facility. When dealing with technology that’s pivotal to your operation, electrical failures can lead to costly downtime, safety hazards, and expensive repairs. The good news is that a significant portion of these failures can be identified and corrected before they occur, thanks to a little-known service that can be a game changer for your facility: infrared thermography.

At Henderson Services, we understand the critical importance of maintaining electrical systems to ensure the long-term safety and efficiency of your facility. Our trained and certified Level II Infrared Thermographers utilize cutting-edge technology and expertise to perform comprehensive assessments, incorporating visual inspections, ultrasonic survey detection, and infrared scanning technology. Utilizing our experience can be the difference between a one-time financial investment and a major financial loss that could take years to recover.

Recently, we had a customer who had completed a brand-new building. While performing preventive maintenance with infrared scans, a critical fault was discovered on some Okonite 15kv service conductors. The critical fault was due to improper installation by the electrical subcontractor during that time. Electrical arcing and hot spots on the cable were detected using a UE Ultrasonic Test Probe and then verified with infrared technology via a Flir E85.

Fortunately, the customer trusted our experts and decided to invest in the proper preventive maintenance services to repair the problem before it got out of hand. They ended up paying $22,985 to complete all of the repairs. This may sound like a large sum, but consider how much it would have cost them when the critical fault failed if they did nothing. Our estimate is that they not only would have incurred over $228,000 in damages but they also would have been faced with threats to the safety of everyone who spent their days inside the building in question.

One of the key benefits of an infrared thermography inspection is its ability to identify potential electrical failures long before they escalate into critical issues, as you can see from our previous example. Studies have shown that up to two-thirds of electrical failures can be detected and corrected during these preventive maintenance inspections. This early detection is crucial in preventing costly downtime and avoiding emergency repairs.

Infrared thermography involves the use of specialized cameras that capture thermal images of electrical components. These images reveal temperature variations in the electrical system, which can signify problems such as loose connections, overloaded circuits, or damaged components. By identifying these issues early, facility managers can schedule maintenance or repairs at their convenience, minimizing disruptions to daily operations.

You may be thinking, “Well, I’ve never heard of this service, it must be some fancy technology that isn’t worth the cost.” However, infrared thermography inspections are a cost-effective form of preventive maintenance. While it may seem like an additional expense, the long-term savings far outweigh the initial investment. By addressing minor electrical issues, you can prevent them from developing into major problems that require extensive repairs or replacements.

Additionally, preventing unplanned downtime due to electrical failures can save your facility from potential revenue losses and the associated costs of emergency repairs. Regular infrared inspections help you maintain a predictable maintenance schedule and budget, reducing the likelihood of unexpected financial burdens.

As mentioned before, at Henderson Services, our Level II Infrared Thermographers go above and beyond to ensure the reliability of your electrical systems. Our comprehensive assessment process combines visual inspections, ultrasonic survey detection, and infrared scanning technology.

Visual inspections help identify obvious issues like loose connections or visible damage to electrical components. Ultrasonic survey detection is used to detect corona discharge, a phenomenon that can lead to electrical failure if left unaddressed. Infrared scanning technology, however, is the centerpiece of our preventive maintenance strategy. Its ability to pinpoint temperature irregularities in your electrical system helps us to locate underlying problems.

In summary, an annual infrared thermography inspection can be a business-changing practice for your facility's electrical maintenance strategy. By identifying and addressing potential issues before they escalate, you can save your facility from costly downtime, emergency repairs, and unexpected financial burdens.

At Henderson Services, we’re committed to helping you maintain the safety and efficiency of your electrical systems through our Level II trained Infrared Thermographers and state-of-the-art technology. Don't wait for electrical failures to disrupt your operations; invest in preventive maintenance today with infrared thermography inspections. Your facility's future depends on it.

You may hear “Infrared Thermography Inspection” and think, Oh, that’s just an add-on service that I don’t need to worry about. According to a study conducted in 2019 by the U.S. Department of Energy, over 2/3 of electrical failures can be identified and corrected before they occur with an annual infrared inspection.

With businesses relying more and more on electrical systems to power their facilities, the importance of regular maintenance and inspections cannot be overstated. Since its creation, Infrared Thermography has revolutionized preventive maintenance for electrical systems. This technology has rapidly gained traction due to its ability to detect issues before they escalate, ensuring zero business interruption and seamless operations. Henderson Services, Kentucky's leading electrical services provider, is at the forefront of utilizing infrared thermography inspections to elevate electrical system reliability and efficiency.

Infrared Thermography is a cutting-edge technology that utilizes thermal imaging cameras to capture the infrared radiation emitted by objects. At Henderson, our Level II trained Infrared Thermographers utilize visual inspections, ultrasonic survey detection, and infrared scanning technology to detect the impending failure of your critical electrical distribution components. Every object with a temperature above absolute zero (-273.15°C or -459.67°F) emits heat in the form of infrared radiation. By detecting and visualizing these temperature inconsistencies, Infrared Thermography allows professionals to identify anomalies in electrical systems, mechanical components, and even building structures.

One of the most significant advantages of infrared thermography inspections is their non-intrusive nature. Traditional methods of inspecting electrical systems often involve shutting down equipment and interrupting business operations. This downtime not only disrupts productivity but also incurs additional costs. In contrast, Infrared Thermography inspections can be carried out without interrupting the ongoing operations, making it a preferred choice for businesses that cannot afford any downtime.

In your business, every minute counts. The ability to maintain and assess electrical systems without causing any interruption can be a game-changer. This makes infrared thermography a valuable tool for companies striving to achieve operational excellence and minimize disruptions.

Imagine being able to identify potential issues in your electrical systems while they are still operational. Infrared Thermography turns this dream into a reality. Skilled technicians equipped with thermal cameras can conduct inspections while machines and equipment are running at full, energized capacity. These inspections can give a glimpse into what it’s like having Superman’s X-ray vision, a powerful ability to discover issues without the need for invasive maneuvers. This real-time monitoring capability allows for the early detection of overheating components, loose connections, and other anomalies that might lead to catastrophic failures if left unaddressed.

The ability to perform inspections while machines are operational is a huge advantage, as it enables businesses to solve problems proactively, preventing unexpected breakdowns and costly repairs. Additionally, this approach enhances safety by reducing the need for manual intervention during inspection periods.

As providers and passionate advocates for preventive maintenance in any business, we recognize the power infrared thermography has in transforming the mindset facility managers have when thinking about protecting their businesses. By implementing regular infrared thermography inspections, businesses can:

Detecting issues early helps prevent potential breakdowns, ensuring uninterrupted operations and customer satisfaction. In addition, knowing the inspection has been done offers you peace of mind that your machinery is functioning properly throughout the day.

Non-intrusive inspections mean less downtime, translating to higher productivity and reduced operational costs.

Identifying and resolving problems before they escalate can extend the lifespan of electrical equipment and systems.

By identifying safety hazards and addressing them promptly, the risk of accidents is significantly reduced.

Proactive maintenance reduces the need for emergency repairs, saving on repair and replacement costs. Your typical Infrared scan of an entire electrical system is usually a fraction of the cost of a replacement should a part fail.

Infrared thermography has transformed the landscape of preventive maintenance, allowing businesses to predict and prevent issues before they disrupt operations. Henderson Services is dedicated to helping Kentucky businesses utilize the power of this technology to achieve unparalleled reliability and efficiency in their electrical systems.

This advanced technique provides invaluable insights into the health of electrical systems. With the ability to perform inspections without causing any interruptions, and even while machines are running, this technology has become an indispensable tool for businesses striving for excellence in preventive maintenance. By utilizing these services, Henderson Services is saving businesses millions of dollars in potential damage repairs every single day. We are committed to leading the charge in utilizing infrared thermography inspections to ensure the reliability and longevity of electrical systems, ultimately contributing to seamless operations and reduced operational costs your business will face.

Contact us today to learn more about how your business can begin implementing preventive maintenance as part of your regular business operations!

Let’s cut straight to the point: if your facility has not completed an Arc Flash Hazard Analysis, you are putting your business and, most importantly, your employees at major risk. Here at Henderson Services, we’ve spent years researching and developing our services in order to serve clients like you as best we can. However, during those years, it has been alarming to see the number of companies that are, at best, generally unaware of the importance that preventive maintenance plays in the health of their company.

When discussing preventive maintenance here at Henderson, it’s much more than a practice you “might as well do.” Instead, it is a life-saving discipline that will set your company apart from all others. One of the areas of preventive maintenance that we see as absolutely vital is Arc Flash Hazard Analysis. But why is it so vital? Afterall, what does it actually accomplish, why do you need it, and how can it affect your team?

An Arc Flash Hazard Analysis is often referred to as an Arc Flash Study. In short, it’s a study of the potential available incident energy specific to electrical equipment during a fault event. It will uncover what hazards and violations exist in your working environment. Due to the rules set in the latest editions of OSHA (29 CFR 1910.269) and NFPA (130.5 C), organizations must conduct this study on their entire facility every five years, accompanied by yearly updates in order to remain compliant and avoid heavy penalties.

As previously mentioned, you need Arc Flash Hazard Analysis to stay compliant with OSHA and NFPA guidelines. Outside of compliance, this study gives you peace of mind, knowing that a complete process to identify any potential electrical hazards has been proactively taken, and any potential power quality issues will be identified to reduce the risk of business interruption. This knowledge of your environment aids you in protecting your employees once work begins. If you haven’t completed your Arc Flash Hazard Analysis, any equipment in the space is not permitted to be used.

Visit our website to see the 7-step process we follow when completing our Arc Flash Hazard Analysis.

Without completing this study, there is no way to know the level of potential energy expressed in calories/cm^2 that an arc flash could emit. This information informs you which level of PPE your employees must wear to meet or exceed the calorie rating on the energized piece of electrical equipment. The last thing you want is to fail to complete your Arc Flash Analysis, send an employee to work on equipment, and unexpectedly have them killed by a lethal amount of electricity. That kind of instance is exactly why regulations for this study exist.

Just as there are labor laws that must be followed for the well-being of your team, working with electricity creates an even greater need for following standards that protect the lives of your employees.

Failing to complete an Arc Flash Analysis for any organization working around hazardous material violates OSHA and NFPA guidelines. In addition, this puts you in danger of being shut down and ultimately losing your business if you fail to comply. Don’t let that be you. To complete your Arc Flash Analysis, simply contact Henderson Services and get a quote today to ensure the safety of your personnel.

The sun is shining, your coffee is hot, and traffic wasn’t too bad this morning. Yet all you can think about is the conversation you had with your supervisor yesterday, who told you that safety is your new priority and it’s up to you to ensure nothing goes wrong.

Perhaps you’ve experienced this exact feeling, or you can empathize with the stressors involved. Whatever the case may be, as a project manager, safety on a project is one of the key responsibilities you must carry. Unfortunately, thousands of electrical-related injuries occur every year, along with hundreds of deaths. The last thing you want for your company is your name associated with that statistic.

So let’s go back to our hypothetical (or very real) situation. Here you are, stressed out, with what feels like the weight of your company’s future on your shoulders. What can you do to ensure your safety culture is where it needs to be?

We advise finding an electrical service at the top of their field. A company that views safety as king and backs it up with results. Such as an OSHA RIR rate of .64, a current EMR of .6, or 0 lost time to injuries in 2022. If that sounds like the kind of company you want to work with, then Henderson Services is a great fit for you.

Here at Henderson, we understand how important your job is and how difficult it can often be with so much on your plate. Our expertise in safety training and preventive maintenance helps us come alongside you and make your job easier. While there are a lot of great electrical contractors out there, there are also some that make you question the quality of their services, the promptness of their response time, and their general care for your team. We understand these fears and have cultivated a company dedicated to serving you at the highest level in all areas.

“Sometimes you find a group that you can trust and that you like doing business with. When you find this group the cost is not really a priority because we know that we are getting the very best service available. Thanks to Henderson, CLARK has found a lasting partnership that supersedes everything else.”

– Bart Ford, General Manager at Clark Material Handling

Your employees are the heart and soul of your business. Care for their well-being is paramount for any successful company. With our NFPA 70E, Lock Out Tag Out, and First Aid, CPR, and AED training, we give you the peace of mind to know that you are following all of the necessary safety-related labor laws.

Take Lock Out Tag Out (LOTO), for instance. Did you know that OSHA estimates that implementing proper LOTO procedures prevents 120 fatalities and 50,000 injuries annually, being that up to 10% of all industrial safety incidents are believed to be related to failure to properly lockout equipment? If you’re reading this and that makes your stomach drop, you probably aren’t alone!

Henderson Services is here to ensure safety becomes a top priority at your company. Check out the video below for more details on the training we offer and how they can set your company up for success.

So if your company is looking to make major improvements regarding the safety procedures set in place, let us help! Don’t let your stress over following safety laws prohibit you from doing the rest of your job well. Henderson Services is here to help you secure your business. Contact us to get a quote.